SSi Artificial Lift’s newest technology, Smart Speed Logic (SSL), is an intuitive technology that allows clients to auto-optimize the wells. SSL takes information from the wells to make ‘smart’ decisions in real time on what the well requires, without requiring an operator.

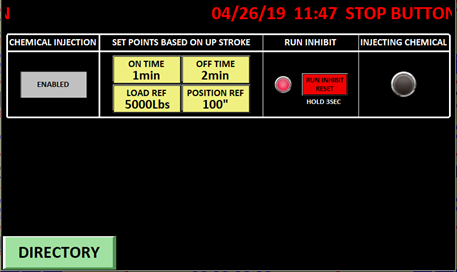

Chemical Injection Control is one of the unique, next generation features, that is included within the Smart Speed Logic. The unit can instruct the chemical injection to start pumping and stop pumping when the previous load is re-acquired indicating that the chemical injection has improved or removed the obstructions.

The current trend in Chemical Injection systems is to alleviate specific downhole problems efficiently with minimal operating costs. This occurs by injecting chemicals at a controlled rate, directly to the source of the problem. Historically, downhole chemicals were utilized by batch injection down the casing or using continuous backside injection, which can be an expensive and wasteful process. It is also less effective than a controlled Chemical Injection feature.

This feature saves costs and time for the operator as there are less chemicals required to be purchased or operators having to travel to the site to switch the pumps on or off.

Additionally, the unit can be easily programmed to inject chemicals based on three different scenarios:

- Load changes due to paraffins, scale, and asphaltene build up

- Stroke position and depth

- Timing – this can be set from 1 – 24 hours

This feature is available on all units with Smart Speed Logic, but any existing units can be easily upgraded. The upgrade can be completed within 15 minutes. It is also compatible with all SCADA System.

Click here to learn more about SSi Artificial Lift Units: https://www.ssilift.com/products/